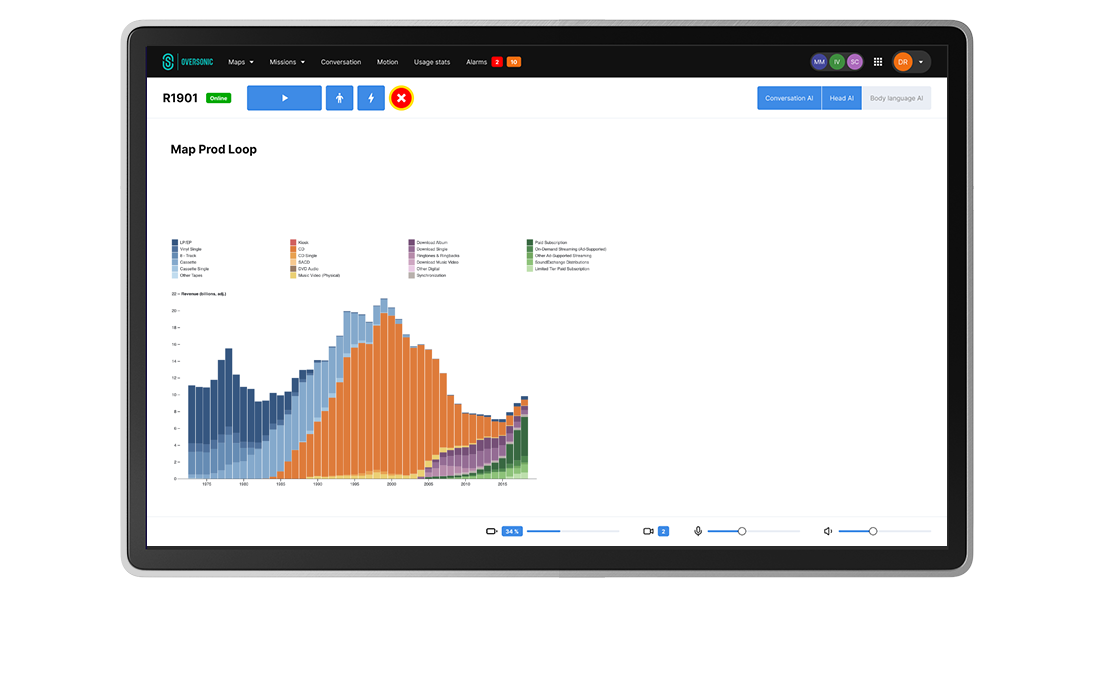

The Monitoring & Analytics module offers a comprehensive view of the robot’s operational health, mission outcomes, and system integrity.

Designed for industrial-grade deployment, it empowers operators with real-time telemetry, historical data analysis, and predictive diagnostics. Each module is continuously tracked to ensure optimal performance and early detection of anomalies.

With customizable KPIs and mission-specific metrics, the platform adapts to diverse operational contexts, supporting both strategic oversight and granular troubleshooting.

| ➔ | Telemetry stream Real-time data flow from all active modules, including motion, sensors, and communication. Enables immediate visibility into RoBee’s behavior and status. |

|---|---|

| ➔ | Predictive maintenance AI-driven analysis of wear patterns and usage cycles. Anticipates component degradation and schedules interventions before failures occur. |

| ➔ | Mission data logs Detailed records of each mission: duration, success/failure status, alerts, and contextual parameters. Useful for performance benchmarking and incident analysis. |

| ➔ | Custom KPIs Configurable performance indicators aligned with industrial goals. Operators can define thresholds and targets based on mission type or operational priorities. |

| ➔ | Battery monitoring Status of up to 6 battery slots per unit. Tracks charge levels, usage rates, and recharge cycles to optimize uptime and energy distribution. |

| ➔ | Zone management Configurable restricted areas, charging stations, and safety zones with access control. |

| ➔ | Component wear status Monitors mechanical stress and usage frequency of critical parts. Flags components approaching end-of-life for timely replacement. |

| Mission outcome charts |

| KPI trand graphs |

| Component wear heatmaps |

| Telemetry dashboard |

| Module-specific performance gauges |

| Data export triggers |

| Customizable notification center |

Mission-centric analytics

Each mission executed by RoBee is logged with precision, capturing outcome metrics, execution time, and any triggered alarms. These logs form the basis for operational reviews and strategic planning. By correlating mission data with environmental variables and robot behavior, operators gain actionable insights into performance bottlenecks and success drivers.

Alarm messages are timestamped and linked to specific modules for faster root-cause analysis.

Cross-module integration

Monitoring extends beyond isolated functions. Navigation paths, conversational exchanges, and sensor feedback are unified into a single analytics layer. This holistic approach allows for pattern recognition across modules — e.g., identifying if navigation errors correlate with low battery or degraded sensor input.

Inter-module correlations can reveal systemic inefficiencies not visible in isolated logs.

Maintenance forecasting

The system continuously evaluates wear indicators and usage intensity across RoBee’s mechanical and electronic components. Predictive models suggest optimal maintenance windows, minimizing downtime and extending hardware lifespan.

Contact us for more detailsMaintenance alerts are prioritized based on mission criticality and component risk level.