The human side of industrial automation.

The manufacturing sector faces structural challenges that go beyond marginal operational issues. Rising workplace injuries, stressful working conditions, and the progressive reduction of available workforce signal an unsustainable trajectory for many operational roles. In the coming decades, the ratio between active and inactive population will continue to decline, making it increasingly difficult to fill essential roles in production processes.

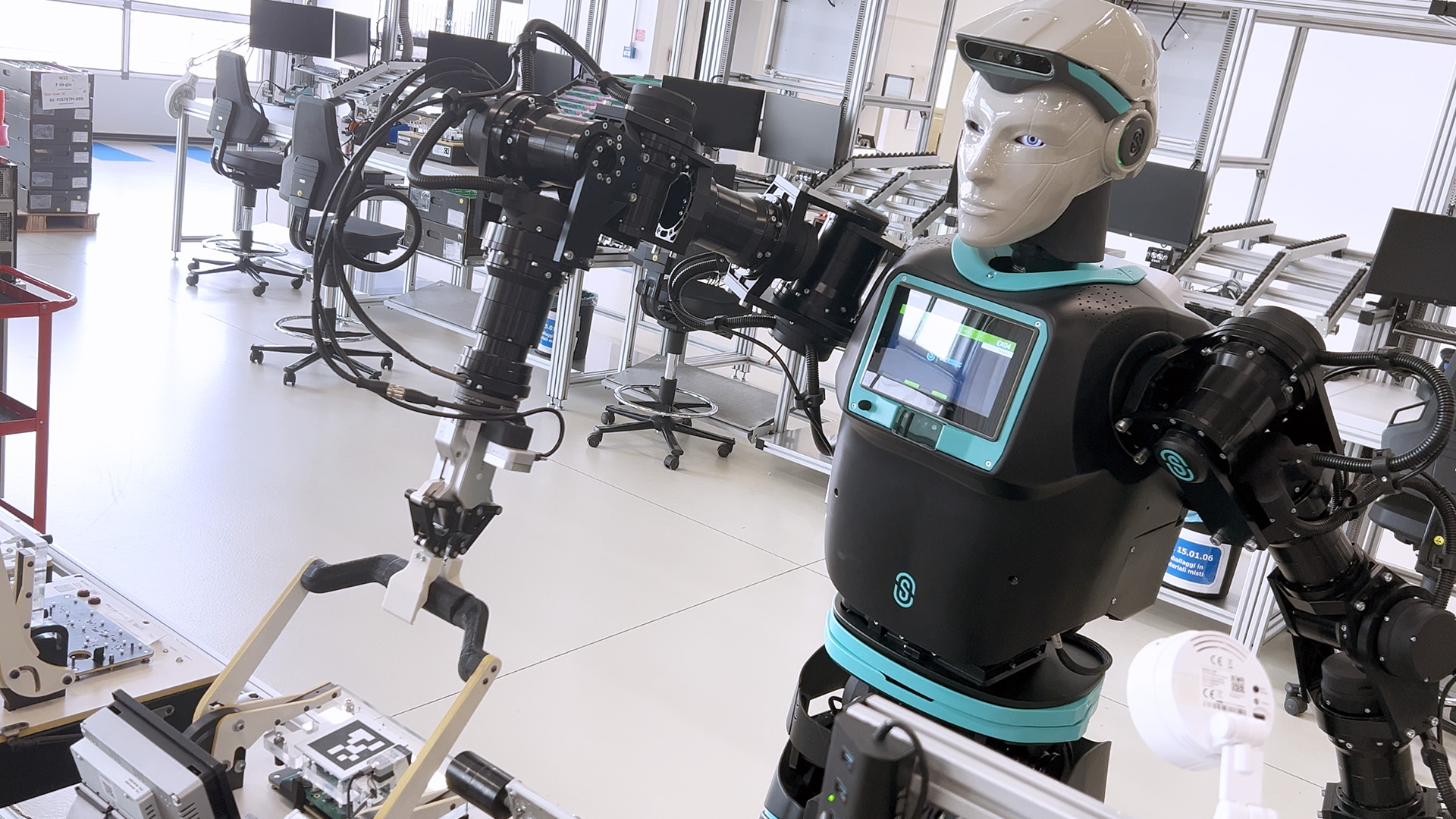

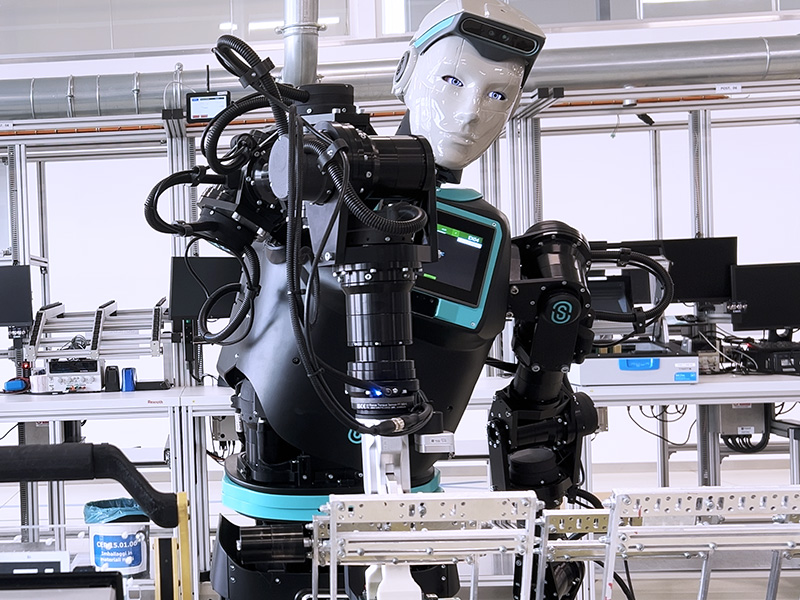

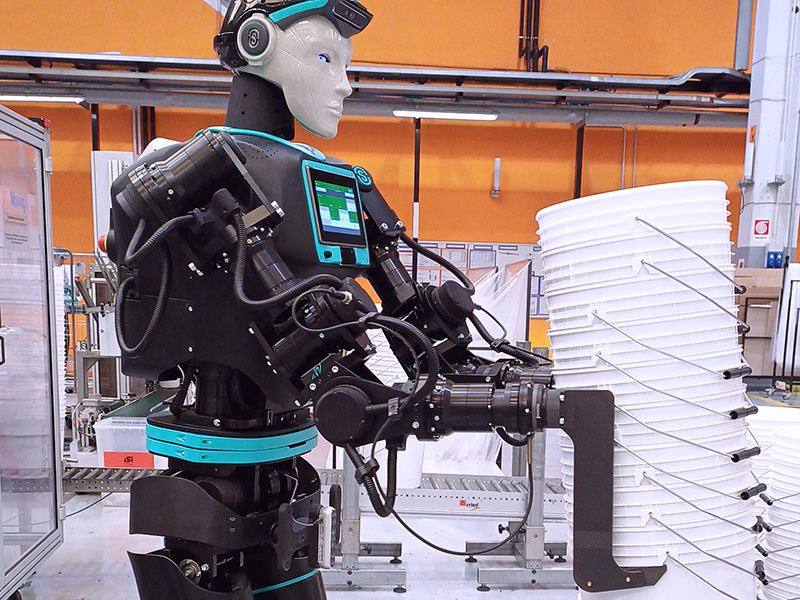

RoBee, Oversonic's cognitive humanoid robot, represents the concrete answer to these emerging industrial needs. Designed to operate alongside people, RoBee embodies a new generation of collaborative technologies capable of contributing to the balance between productivity, human wellbeing, and operational continuity.

Explore RoBee RWork contexts and people's expectations are changing, requiring industry to ensure greater safety and better psychophysical balance for workers.